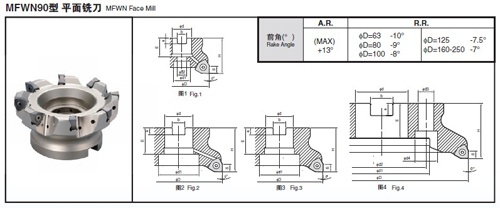

京瓷 双面6刀尖 低阻力90°铣刀MFWN型产品介绍

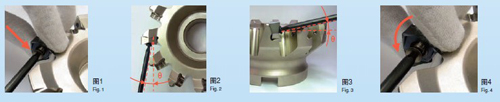

■交换刀片的顺序 How to mount an insert

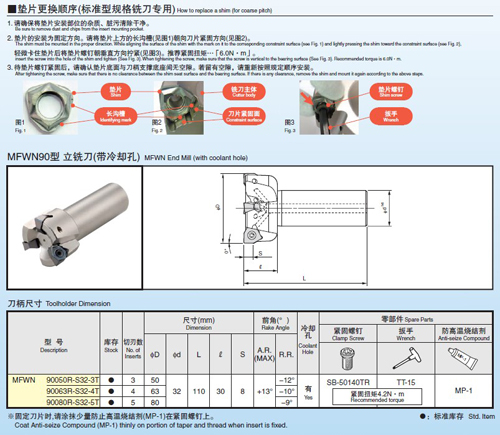

1. 刀片安装部位中切屑等杂物请清除干净。

Be sure to remove dust and chips from the insert mounting pocket.

2. 紧固螺钉的锥形部位与螺纹部位涂覆防高温烧结剂后,安装于扳手尖端,将刀片往固定方向轻按住后,紧固。(见图1) 。

After applying anti-seize compound on portion of taper and thread, attach the screw to the front end of the wrench. While lightly pressing the insert against the constraint surfaces, put the screw into the hole of the insert and tighten. (See Fig. 1)

3. 扳手请与紧固螺钉呈平行方向紧固。

When tightening the screw, make sure that the wrench is parallel to the screw.

另外,部分超多刀刃型规格的铣刀,相对刀片上部螺孔呈倾斜状态,请充分注意(见图2、图3)。

Remember that the screw hole of the holder for Extra fine pitch is inclined to the bearing surface.(See Fig. 2 and Fig. 3)

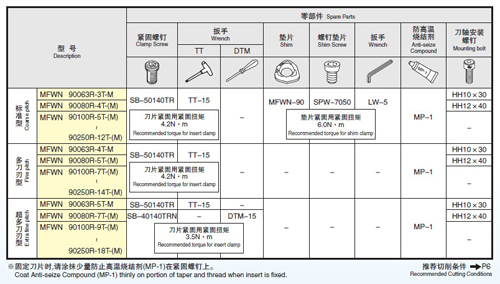

4. 刀柄螺钉请使用正确扭矩紧固。推荐紧固扭矩为

Be careful not to tighten the screw with excessive torque. Recommended torque is

M5螺钉(SB-50140TR):4.2N·m M4螺钉(SB-40140TRN):3.5N·m

4.2N·m for M5 screw (SB-50140TR) and 3.5N·m for M4 screw (SB-40140TRN).

5. 紧固后,刀片底座与刀柄的支撑底座、以及刀片侧面与固定面之间,请确保无缝隙。若有缝隙,请重新按规定顺序安装。

After tightening the screw, make sure that there is no clearance between the insert seat surface and the bearing surface of the holder or between the insert side surfaces and the constraint surface of the holder. If there is any clearance, remove the

insert and mount it again according to the above steps.

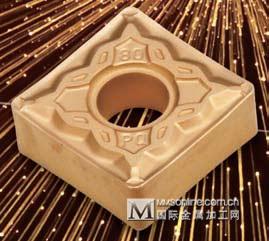

6. 逆时针方向旋转刀片来更换刀片的切刃(见图4)。刀片上面有切刃编号,请按顺序使用。

To change the cutting edge of the insert, turn the insert counterclockwise. (See Fig. 4) The insert corner identification number is stamped on the top surface of the insert.

|

|

|

| 电话: | 021-36607711 |

| 传真: | 021-56386200 |

| 地址: | 上海市闸北区万荣路700号大宁中心广场A3幢140室 |

Copyright ©1997-2024 mmsonline.com.cn . All rights reserved.

官方微博

官方微博

CA515/CA525钢加工新CVD涂层

CA515/CA525钢加工新CVD涂层 高效率加工 Axel系列3ZFK型

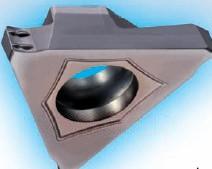

高效率加工 Axel系列3ZFK型 3刀尖型GBA型

3刀尖型GBA型 高效率加工 Axel系列4MFK铣削

高效率加工 Axel系列4MFK铣削 面4刀尖式样 新型端铣刀MEW

面4刀尖式样 新型端铣刀MEW